This article was originally published by the Florida Engineering Society, OCTOBER 2021

This article presents an innovative approach to supplement traditional bridge inspection and asset management programs by using advanced technologies such as 3D scanning, drones, Light Detection and Ranging (Lidar), Artificial Intelligence (AI) and health monitoring. The use of advanced technologies is to improve public safety and to support Bridge Owners in the development and maintenance of an efficient Bridge Inspection and Rehabilitation Work Program. This paper will discuss the following: an analytic database approach to plan and execute the inspection operations; the use of a 3D Scanning process to obtain an accurate and realistic Point Cloud Bridge Model; and the ability to perform visual inspection directly from office workstations. Additionally, it will discuss the ability to make accurate diagnoses on all defects of the asset even without going on-site (including defects in areas otherwise inaccessible) and the use of AI techniques to screen and pre-classify any defects.

According to the Federal Highway Administration’s (FHWA) National Bridge Inspection Standards (NBIS): “The FHWA bridge inspection program regulations were developed as a result of the Federal-Aid Highway Act of 1968 that required the Secretary of Transportation to establish NBIS to ensure the safety of the traveling public.”[1] Historically, bridge inspectors have primarily relied on visual inspections to evaluate the condition of individual bridge components and subsequently the condition of the complete structure. Data derived from physical condition inspections and other data such as geometry, detour length and average daily traffic provide a generalized rating, termed Sufficiency Rating (SR).

SRs have been used by bridge owners to indicate the structure’s sufficiency to remain in service. The result of this method is a percentage in which 100 percent would represent an entirely sufficient bridge and zero percent would represent an entirely insufficient or deficient bridge. As a tool for bridge owners to ensure the safety of the traveling public and plan to manage the safe extension of the structure’s remaining service life, the implementation of technology such as 3D scanning, drones, Lidar, Artificial Intelligence and Health Monitoring Sensors may prove to be the path of the future.

The FHWA Recording and Coding Guide for the Structure Inventory and Appraisal of the Nation’s Bridges defines the SR as a weighted average of structural adequacy and safety, serviceability and functional obsolescence, essentiality for public use and allows for limited deductions. [2] Structural adequacy accounts for 55% of the SR. Therefore, accurate inspections are a vitally

important planning tool for public safety and asset management.

Although State Departments of Transportation (DOT) have employed additional methods to complement visual inspection, the use of Nondestructive Evaluation (NDE) technologies is considered to solve difficult inspection challenges that are beyond the capability of normal visual inspections.[3] These technologies are being researched for implementation into bridge inspection and asset management plans. The ARGO platform, developed by MOVYON to create technological solutions for safer infrastructure and sustainable mobility, can be a potential solution for bridge owners.

Although State Departments of Transportation (DOT) have employed additional methods to complement visual inspection, the use of Nondestructive Evaluation (NDE) technologies is considered to solve difficult inspection challenges that are beyond the capability of normal visual inspections.[3] These technologies are being researched for implementation into bridge inspection and asset management plans. The ARGO platform, developed by MOVYON to create technological solutions for safer infrastructure and sustainable mobility, can be a potential solution for bridge owners.

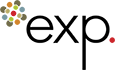

The ARGO platform involves the digital tracking of all parameters affecting complex infrastructures, such as viaducts, bridges, and tunnels. Infrastructure safety is the main goal and involves two main activities: inspection and monitoring. Inspection occurs visually, with an inspector physically traveling to the bridge to document deficiencies and defects. The system inventories the elements of the assets in a database. The bridges are broken down into elements and coded in their typology, according to the different structures, including dimensions. From this inventory work, a simplified 3D model is built from the database. This allows the inspector who goes to the site, through their tablet, to “see” the simplified 3D model of the bridge and place any defects found directly on the correct database element (Figure 1).

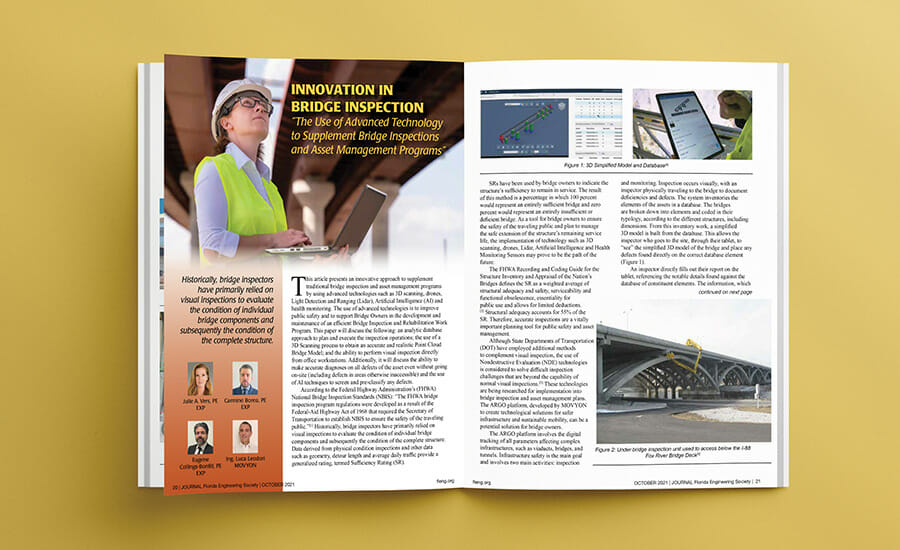

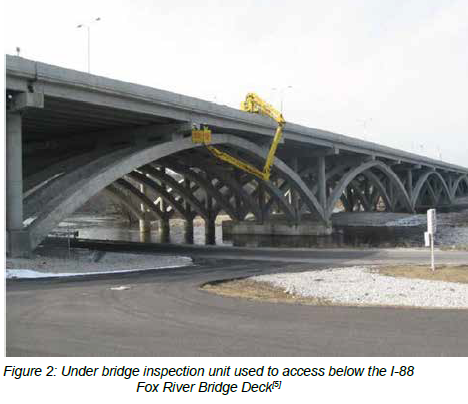

An inspector directly fills out their report on the tablet, referencing the notable details found against the database of constituent elements. The information, which includes images of the defect, is codified and localized. This information can be used in future inspections also to evaluate the evolution of the structural condition. In traditional bridge inspection, special means are needed to allow the bridge inspector to go below the bridge deck to assess components that are otherwise inaccessible (Figure 2). Having modeled the bridge in its constituent components, a further step can be taken: 3D scanning (Figure 3).

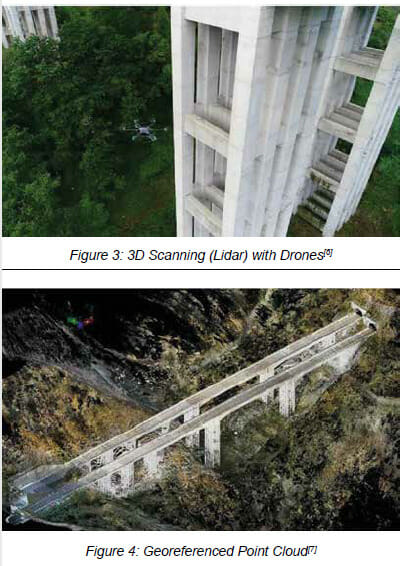

The 3D scanning is achieved using special drones. The Lidar that serves to make the 3D scan is positioned above the drone, in union with two cameras, and not below as usual. This allows a full and precise scan of less visible areas from under the bridge. With the drone approximately 30 feet away from the structure, the accuracy of the Lidar detection used is exact. The drone is brought to the bridge and then flown locally to perform a laser scan that takes a day, on average. The drone transforms the infrastructure into millions of points, each georeferenced in space with their x, y and z coordinates (Figure 4).

The 3D scanning is achieved using special drones. The Lidar that serves to make the 3D scan is positioned above the drone, in union with two cameras, and not below as usual. This allows a full and precise scan of less visible areas from under the bridge. With the drone approximately 30 feet away from the structure, the accuracy of the Lidar detection used is exact. The drone is brought to the bridge and then flown locally to perform a laser scan that takes a day, on average. The drone transforms the infrastructure into millions of points, each georeferenced in space with their x, y and z coordinates (Figure 4).

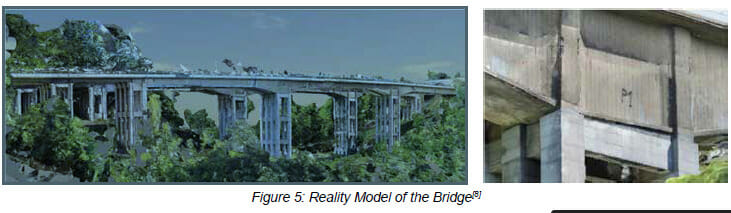

Once this is completed, the drone takes a sequence of georeferenced photographs and “dresses” the model with the texture obtained from the photos generating a “reality model of the bridge” (Figure 5). At that point, it is possible to see and measure a defect, with the same resolution the inspector would see from less than an arm’s length. After the first flight of 3D modeling and point cloud reconstruction, subsequent drone inspections, which serve to collect new photos, could be performed semi-automatically.

In this case, the drone follows a preset flight plan and automatically collects the necessary images in the shortest time possible. It is possible to update the images of two or three bridges in a single day of flight. All this information could be associated with data from a thermal camera scan of the bridge to correlate it with the other elements. For example, if there is a void behind a concrete surface because it is delaminated, neither Lidar nor optical analysis shows anything abnormal, but a thermal camera will reveal the defect.

Per the NBIS, a close-up, in-depth inspection of one or more members above or below the water level may be required to identify any deficiencies not readily detectable using routine inspection procedures; hands-on inspection may be necessary at some locations.[1] The use of this advanced technology provides access and accuracy to bridges with inaccessible structural components.

This approach of implementing technology may allow remote inspections with greater frequency. Additionally, AI technology can be incorporated to screen and “pre-classify” any deficiencies/defects. The goal is to allow inspectors, from their office workstations, to make accurate diagnoses on all defects of the asset even without going on-site, including defects in areas otherwise inaccessible. In the first phase of validation, the bridge inspector will continue to go on-site and verify if the diagnosis made by the AI corresponds to what has been visually detected. This will confirm the quality and accuracy of the AI work or provide data to refine the neural network.

In conjunction with the above, structure monitoring through sensors is a key element to ensuring safety and keep monitoring the behavior of the structure. The inspector captures the actual structure condition, and the sensor monitoring generates data that is analyzed over a longer period.

The Technology-Integrated Structural inspection flow may be summarized in the following points:

• Visual inspection, with an inspector physically traveling to the bridge to document deficiencies and defects

• Determine structures that would benefit from advanced technology inspection techniques

• Build 3D model

• Perform 3D scan using Lidar for a refined model

• Perform thermal scan, if necessary

• Use Artificial Intelligence to “pre-classify” defects

• Validate the diagnosis by having the bridge inspector go on-site and verify if the diagnosis made by the artificial intelligence corresponds to what has been visually detected

• Install sensors and monitor structure

• Provide a product to bridge owners that is more valuable than current SR for asset management

In conclusion, traditional bridge inspection methods integrated with applicable advanced technology may be the most beneficial for ensuring public safety, extending the structure’s service life and building an asset management plan for structures’ owners.

For more information on this article and the expertise involved, contact: